Bottom price Edd Cold Rolled Steel Coil - Cold rolled steel sheet plate for building materials industry – Ruigang

Bottom price Edd Cold Rolled Steel Coil - Cold rolled steel sheet plate for building materials industry – Ruigang Detail:

Product Details

Cold-rolled sheet is a product obtained by rolling hot-rolled coils at room temperature below the recrystallization temperature. Mostly used in automobile manufacturing, electrical products, etc. Cold rolling is rolling at the recrystallization temperature, but is generally understood as rolling using a material rolled at room temperature. Editing of cold-rolled sheet production process 1. Since there is no heating during the production process, there are no defects such as pitting and iron oxide scale that often occur in hot rolling, and the surface quality is good and the finish is high. And the dimensional accuracy of cold-rolled products is high.

Advantages of cold rolled sheet

Cold-rolled coil products have precise dimensions and uniform thickness, and the thickness difference of coils is generally not more than 0.01-0.03mm or less, which can fully meet the requirements of high-precision tolerances.

Very thin strips that cannot be produced by hot rolling (the thinnest can be below 0.001mm) can be obtained.

The surface quality of cold-rolled products is excellent, and there are no defects such as pitting and iron oxide scale that often occur in hot-rolled coils, and coils with different surface roughness (glossy surface or rough surface, etc. ) to facilitate the processing of the next process.

Cold-rolled sheets have good mechanical properties and process properties (such as higher strength, lower yield limit, good deep drawing performance, etc.)

The difference between cold rolled sheet and hot rolled sheet

The difference is that the definition is different, the performance is different, and the price is different. The cold-rolled sheet is rolled at room temperature, so its hardness is higher, the strength is higher, it is not easy to deform, and the surface finish is high, but it is easy to be loaded when the load exceeds the allowable load. Accidents occur. Hot-rolled sheets are rolled at high temperature, and their mechanical properties are not as good as those of cold working, but they have good toughness and ductility, but are prone to form iron oxide scale, which makes the surface of the steel rough, the size fluctuates greatly, and the price is also high. lower than cold rolled sheet.

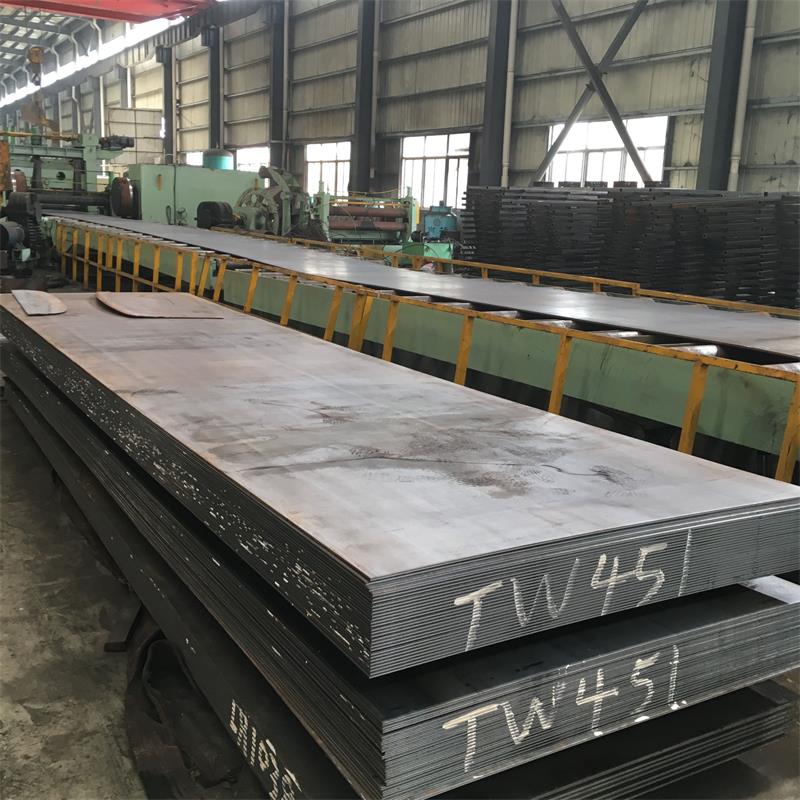

Product detail pictures:

Related Product Guide:

With our excellent administration, strong technical capability and strict excellent control method, we carry on to offer our clients with responsible good quality, reasonable costs and great companies. We intention at becoming considered one of your most responsible partners and earning your pleasure for Bottom price Edd Cold Rolled Steel Coil - Cold rolled steel sheet plate for building materials industry – Ruigang, The product will supply to all over the world, such as: Johor, Cancun, Azerbaijan, Hard work to keep making progress, innovation in the industry, make every effort to first-class enterprise. We try our best to build the scientific management model, to learn abundant experienced knowledge, to develop advanced production equipment and production process , to create the first-call quality goods, reasonable price , high quality of service , quick delivery , to present you create new value .

In our cooperated wholesalers, this company has the best quality and reasonable price, they are our first choice.