Cold Rolled Galvanized Steel Coil - Cold Rolled Steel Sheet Coil – Ruigang

Cold Rolled Galvanized Steel Coil - Cold Rolled Steel Sheet Coil – Ruigang Detail:

Product Details

Thickness is 0.1-8mm

Width is 600-2 000mm

The length of the steel plate is 1 200-6 000mm

Grades: Q195A-Q235A, Q195AF-Q235AF, Q295A(B)-Q345 A(B); SPCC, SPCD, SPCE, ST12-15; DC01-06 DC01-DC06 CR220IF HC340LA 590DP 220P1 CR220BH CR42 DC01-DC06 SPCC-J1 SPCC-J2 SPCD SPCE TYH THD SPCC-SC TLA SPCC DC01

Product Introduction

Using hot-rolled steel coil as raw material, after pickling to remove oxide scale, cold continuous rolling is carried out, and the finished product is rolled hard coil. The cold work hardening caused by continuous cold deformation increases the strength, hardness and toughness and plastic index of rolled hard coil. , so the stamping performance will deteriorate and can only be used for parts with simple deformation. Hard-rolled coils can be used as raw material for hot-dip galvanizing plants, because hot-dip galvanizing lines are equipped with annealing lines. The weight of the rolled hard coil is generally 20-40 tons, and the hot-rolled pickled coil is continuously rolled at room temperature. The inner diameter is 610mm.

Product Features

Because it has not been annealed, its hardness is very high (HRB is greater than 90), and its machinability is extremely poor, so it can only perform simple directional bending less than 90 degrees (perpendicular to the coiling direction).

To put it simply, cold rolling is processed and rolled on the basis of hot rolled coils. Generally speaking, it is a process of hot rolling—pickling—cold rolling.

Cold-rolled is processed from hot-rolled sheets at room temperature. Although the temperature of the steel sheet will be heated during the processing, it is still called cold-rolled. Due to the continuous cold deformation of hot rolling, the mechanical properties are relatively poor and the hardness is too high. It must be annealed to restore its mechanical properties, and those without annealing are called hard rolled coils. Hard-rolled coils are generally used to make products that do not require bending or stretching, and those with a thickness of less than 1.0 are rolled on both sides or four sides with good luck.

Application

Cold-rolled strips are widely used, such as automobile manufacturing, electrical products, rolling stock, aviation, precision instruments, canned food, etc. Cold-rolled sheet is the abbreviation of ordinary carbon structural steel cold-rolled sheet, also known as cold-rolled sheet, commonly known as cold-rolled sheet, and sometimes mistakenly written as cold-rolled sheet. The cold plate is a hot-rolled steel strip of ordinary carbon structural steel, which is further cold-rolled into a steel plate with a thickness of less than 4mm. Due to rolling at room temperature, no scale is produced, therefore, the cold plate has good surface quality and high dimensional accuracy, coupled with annealing treatment, its mechanical properties and process properties are better than hot-rolled steel sheets, in many fields, especially In the field of home appliance manufacturing, it has gradually replaced hot-rolled sheet steel.

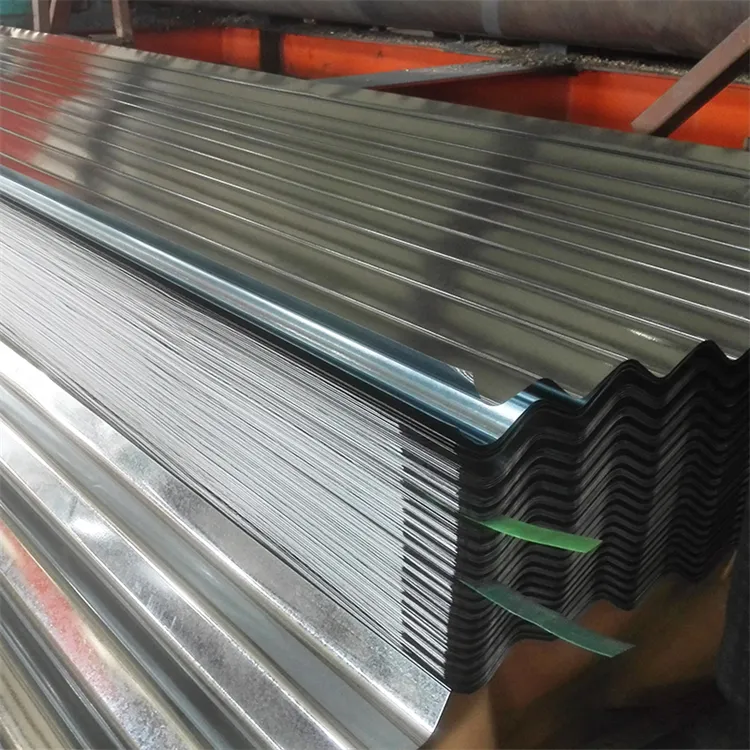

Product detail pictures:

Related Product Guide:

All we do is always involved with our tenet " Consumer initial, Trust first, devoting within the food stuff packaging and environmental defense for Cold Rolled Galvanized Steel Coil - Cold Rolled Steel Sheet Coil – Ruigang, The product will supply to all over the world, such as: Portland, Yemen, Somalia, The company has perfect management system and after-sales service system. We devote ourselves to building a pioneer in the filter industry. Our factory is willing to cooperate with different customers domestic and overseas to gain better and better future.

Good quality, reasonable prices, rich variety and perfect after-sales service, it's nice!