Factory made hot-sale Prime Hot Rolled Steel Sheets - Steel Coil – Ruigang

Factory made hot-sale Prime Hot Rolled Steel Sheets - Steel Coil – Ruigang Detail:

Product Specifications

Thickness: 0.2-20mm

Width: 600-3000mm

Formed coils are mainly hot-rolled coils and cold-rolled coils. Hot rolled coil is the processed product before the recrystallization of the steel billet. Cold rolled coil is the subsequent processing of hot rolled coil. The general weight of the steel coil is about 15-30T.

Product Classification

● Hotrolled, that is, hot-rolled coil, which is a slab (mainly for.

● Casting billet) as raw material, after heating, it is made into strip steel by rough rolling unit and finishing rolling unit.

● The hot strip from the last rolling mill of finishing rolling is cooled by laminar flow to the set point.

● The coil is rolled into a steel strip coil by a coiler, and the cooled steel strip coil can be used according to the different needs of users.

● After different finishing lines (leveling, straightening, cross-cutting or slitting, inspection.

● Weighing, packaging and marking, etc.) are processed into steel plates, flat coils and slit steel strip products.

production process

The production process of hot-dip galvanized sheet mainly includes: Original plate preparation → Pre-plating treatment → Hot dip plating → Post-plating treatment → Finished product inspection, etc. According to custom, often according to the pre-plating treatment method of.

The galvanized coil is composed of an aluminum-zinc alloy structure, which is composed of 55% aluminum, 43% zinc and 2% silicon solidified at a high temperature of 600 ° C. The entire structure is composed of aluminum-iron-silicon-zinc, forming a dense A kind of quaternary knot body.

Product Details

Material: Q235B, Q345B, SPHC510LQ345AQ345E

Cold rolled coil (Coldrolled), commonly used in the steel industry, is different from hot rolled coil.

It refers to directly rolled into a certain thickness with a roll at room temperature and rolled into a whole roll with a winder

steel belt. Compared with hot-rolled coils, cold-rolled coils have a brighter surface and higher finish, but will

More internal stress is generated, and annealing treatment is often carried out after cold rolling.

Category: SPCC, SPCD, SPCE

Galvanized steel coils (Galvanized steel coils), galvanized refers to the metal, alloy or the surface of other materials is plated with a layer of zinc to play the role of beautiful, rust-proof and other surface treatment technology. Now the main method is hot-dip galvanizing.

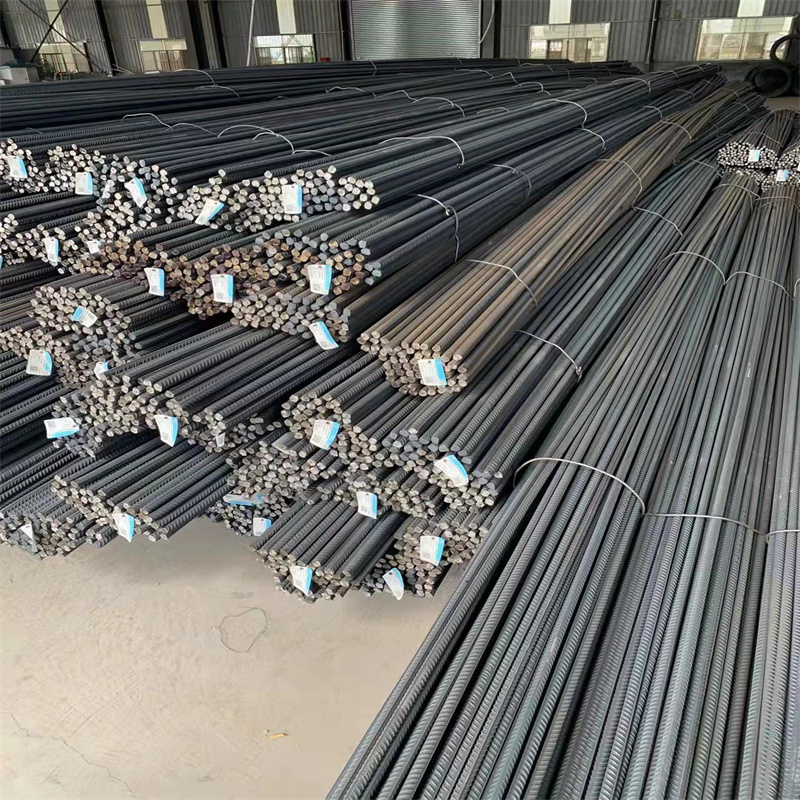

Product detail pictures:

Related Product Guide:

We take "customer-friendly, quality-oriented, integrative, innovative" as objectives. "Truth and honesty" is our management ideal for Factory made hot-sale Prime Hot Rolled Steel Sheets - Steel Coil – Ruigang, The product will supply to all over the world, such as: Southampton, Surabaya, Mauritius, Taking the core concept of "to be the Responsible". We'll redound up on society for high quality merchandise and good service. We will initiative to participate in international competition to be a first- class manufacturer of this product in the world.

The company's products can meet our diverse needs, and the price is cheap, the most important is that the quality is also very nice.