Galvanized Steel Coil With Color Coating - Hot dipped Steel Zinc Coated Galvanized Steel Coil Corrugated Sheet – Ruigang

Galvanized Steel Coil With Color Coating - Hot dipped Steel Zinc Coated Galvanized Steel Coil Corrugated Sheet – Ruigang Detail:

Product Specifications

Thickness: 0.3-10mm

Width: 600-2500mm

Specifications: CGC340 CGC400 CGC440 Q/HG008-2014 Q/HG064-2013

GB/T12754-2006 DX51D+Z CGCC Q/HG008-2014 Q/HG064-2013 GB/T12754-2006 CGCD1 TDC51D+Z

Uses:

1 Architectural applications

The outdoor construction industry is mainly: roofs, roof structures, balcony panels, water slides, window frames, gates, garage doors, rolling shutter doors, kiosks, shutters, guard houses, simple houses, refrigerated vehicles, etc.

Indoor applications are mainly: door, partition, door frame, house light steel structure, sliding door, screen, ceiling, bathroom interior, elevator interior, elevator lobby, etc.

2. Application on electrical appliances

Refrigerator, washing machine, electric oven, vending machine, air conditioner, copier, electric fan.

3. Application in transportation

Car ceilings, back panels, hoardings, interior decorative panels, car shells, trunk panels, cars, dashboards, console shells, trams, train ceilings, partitions, inner walls, ship color boards, doors, floors, containers, etc.

4. Application of sheet metal processing and furniture

Ventilation heaters, water heater shells, counters, shelves, signboards, wardrobes, tables, bedside tables, chairs, dressing boxes, filing cabinets, bookshelves, etc.

Color Coating Roll Application

Color-coated coils are light, beautiful and have good anti-corrosion properties, and can be directly processed. The colors are generally divided into gray-white, sea-blue and brick red. They are mainly used in advertising, construction, household appliances, electrical appliances, furniture and transportation. Industry.

Classification

Hot dip galvanized substrate

The product obtained by coating the organic coating on the hot-dip galvanized steel sheet is the hot-dip galvanized color-coated sheet. In addition to the protective effect of zinc, the organic coating on the surface of the hot-dip galvanized color-coated sheet also plays the role of insulation and protection, preventing rust, and the service life is longer than that of the hot-dip galvanized sheet. The zinc content of the hot-dip galvanized substrate is generally 180g/m2 (double-sided), and the maximum galvanized amount of the hot-dip galvanized substrate for building exterior is 275g/m2.

Hot-dip Al-Zn substrate

The hot-dip galvanized steel sheet (55% Al-Zn) is used as the new coating substrate, and the content of aluminum and zinc is usually 150g/㎡ (double-sided). The corrosion resistance of hot-dip galvanized sheet is 2-5 times that of hot-dip galvanized sheet. Continuous or intermittent use at temperatures up to 490°C will not severely oxidize or produce scale. The ability to reflect heat and light is 2 times that of hot-dip galvanized steel, and the reflectivity is greater than 0.75, which is an ideal building material for energy saving.

Electro-galvanized substrate

The electro-galvanized sheet is used as the substrate, and the product obtained by coating organic paint and baking is electro-galvanized color-coated sheet. Because the zinc layer of the electro-galvanized sheet is thin, the zinc content is usually 20/20g/m2, so this product is not suitable for use. Make walls, roofs, etc. outdoors. But because of its beautiful appearance and excellent processing performance, it can be mainly used in home appliances, audio, steel furniture, interior decoration, etc.

Characteristics

Electro-galvanized substrate: the coating is thinner, and its corrosion resistance is not as good as that of hot-dip galvanized substrate;

Hot-dip galvanized substrate: The thin steel plate is immersed in a molten zinc bath to make a layer of zinc adhere to the surface. This galvanized plate has good adhesion and weldability of the coating.

Hot-dip Al-Zn substrate:

The product is plated with 55% AL-Zn, has excellent anti-corrosion performance, and its service life is more than four times that of ordinary galvanized steel. It is a replacement product of galvanized sheet.

Features

(1) It has good durability, and its corrosion resistance is longer than that of galvanized steel;

(2) It has good heat resistance and is less prone to discoloration at high temperature than galvanized steel;

(3) It has good thermal reflectivity;

(4) It has processing performance and spraying performance similar to galvanized steel sheet;

(5) It has good welding performance.

(6) It has a good price-performance ratio, durable performance and very competitive price. Therefore, whether architects, engineers or manufacturers have been widely used in industrial buildings, steel structures and civil facilities, such as: garage doors, gutters and roofs, etc.

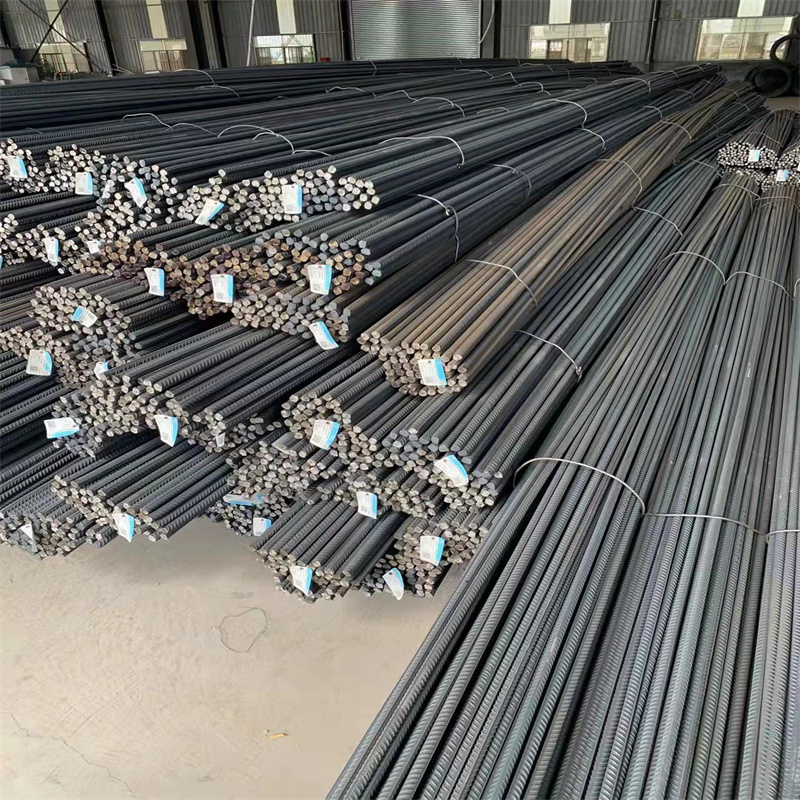

Product detail pictures:

Related Product Guide:

Each individual member from our large performance revenue crew values customers' needs and company communication for Galvanized Steel Coil With Color Coating - Hot dipped Steel Zinc Coated Galvanized Steel Coil Corrugated Sheet – Ruigang, The product will supply to all over the world, such as: Roman, Moldova, Oman, Our products are exported worldwide. Our customers are always satisfied with our reliable quality, customer-oriented services and competitive prices. Our mission is "to continue to earn your loyalty by dedicating our efforts to the constant improvement of our items and services in order to ensure the satisfaction of our end-users, customers, employees, suppliers and the worldwide communities in which we cooperate".

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.