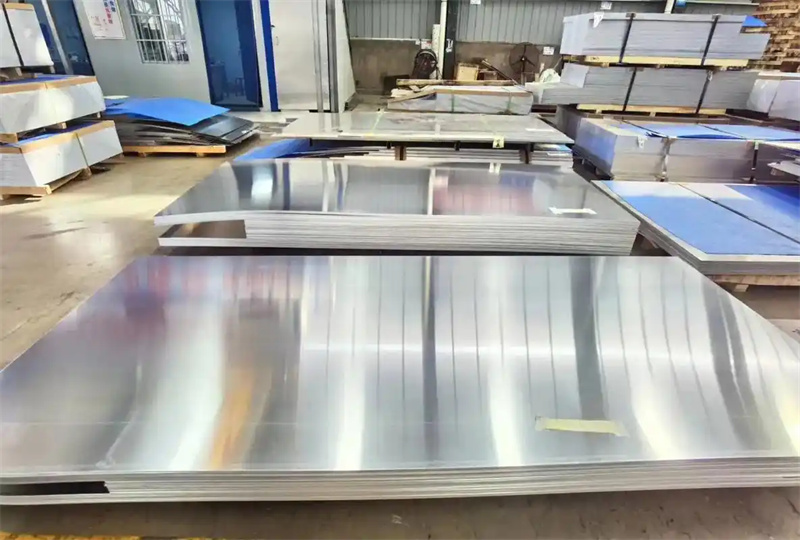

Shandong Kungang Metal Technology Co., Ltd. mainly produces 1050 aluminum plate, 1060 aluminum plate, 1100 aluminum plate, 3003 aluminum plate, 5052 aluminum plate, 5083 aluminum plate, 8011 aluminum plate and other alloy aluminum plates and aluminum coils. The product thickness ranges from 0.3mm-6.0mm, the product width is 800mm-2000mm, and the plate length is 800mm-8000mm. The annual production capacity is 300,000 tons.

The core representative product of the 3XXX series, 3003 aluminum plate, is usually also called alloy aluminum plate or alloy aluminum plate by friends. Of course, no matter how it is called, it is enough to find out how popular 3003 aluminum plate is in our civilian field. As the most commonly used aluminum plate product in daily life, 3003 aluminum plate is also a representative product of the aluminum-manganese alloy series, which is enough to show the excellent performance of 300 aluminum plate.

Usually, we like to compare 3003 aluminum plate with 1060 aluminum plate, because most of the 1 series and 3 series aluminum plates are mainly used for single plate or exterior wall construction, so we usually like to compare the two. Through comparison, we can easily find that the strength of 3003 aluminum plate is about 10%-20% higher than that of 1100 aluminum plate and 1060 aluminum plate, especially the 3003 aluminum plate with manganese alloy, which is better than the 1 series in solubility, corrosion resistance and forming performance.

3003 aluminum plate is AL-Mn alloy, which is a widely used rust-proof aluminum. The compressive strength of this type of alloy is not high (slightly higher than industrial pure aluminum), and it cannot be strengthened by heat treatment. Therefore, cold drawing is used to improve its physical properties: it has high plasticity in quenching, good plasticity in semi-cold hardening, low plasticity in cold hardening, good corrosion resistance, excellent electric welding, and poor machinability. Mainly used for parts that require high plasticity and good weldability, low-load parts working in liquid or gaseous media, such as fuel tanks, gasoline or grease hoses, various liquid containers and other small-load parts made by deep drawing: cables are used to make bolts.

3003 aluminum plate is a typical Al-Mn anti-rust alloy. The addition of the alloying component Mn slightly increases the compressive strength while maintaining the excellent processing properties and corrosion resistance of pure aluminum. 3003 aluminum plate is an unheat-treated alloy and cannot be strengthened by heat treatment, so the traditional cold drawing method can improve its physical properties. In addition, 3003 aluminum plate has the advantages of excellent weldability, formability, etc., and has become a popular and economical choice for “electrical parts”. In addition to common specifications, CHAL Aluminum Corporation can also produce 3003 ultra-high and extra-thick aluminum plates. The internal stress of these plates is eliminated and they do not deform during the laser cutting process. The maximum width is 2650mm and the maximum thickness is 500mm.

The aluminum plates and aluminum coils we produce are widely used in engineering decoration, home decoration, communications electronics, transportation facilities, thermal insulation and anti-corrosion, fine decoration, automobile manufacturing and other fields, and are widely used. Among them, product stamping relies on the stability of Taicheng Aluminum’s product quality

Post time: Mar-19-2025