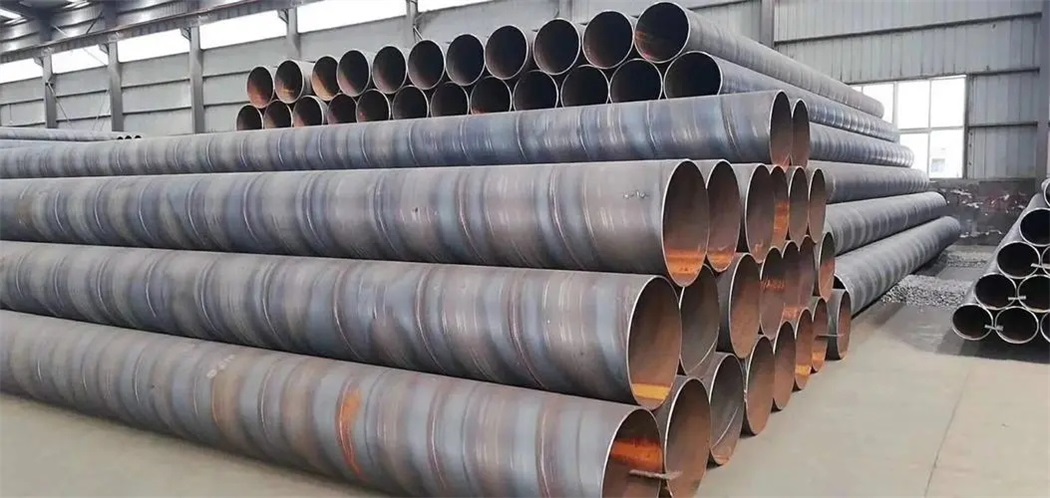

Introduction to Shandong Kungang Spiral Pipe

The spiral pipe is made by rolling low-carbon carbon structural steel or low-alloy structural steel strip into a tube blank according to a certain helical angle (called the forming angle), and then welding the pipe seams. It can be made with a narrower strip Steel produces large diameter steel pipes. Its specifications are expressed by outer diameter * wall thickness. The welded pipe should ensure that the hydraulic test, the tensile strength of the weld and the cold bending performance must meet the regulations.

In terms of welding process, the welding method of spiral welded pipe and straight seam steel pipe is the same, but the straight seam welded pipe will inevitably have a lot of T-shaped welds, so the probability of welding defects is also greatly increased, and the welding residue at the T-shaped welds The stress is large, and the weld metal is often in a three-dimensional stress state, which increases the possibility of cracks. Moreover, according to the technical regulations of submerged arc welding, each weld should have an arc starting point and an arc extinguishing point, but each straight seam welded pipe cannot meet this condition when welding a circular seam, so there may be More welding defects.

use

Spiral pipes are mainly used in water supply engineering, petrochemical industry, chemical industry, electric power industry, agricultural irrigation, and urban construction. It is one of the twenty key products developed by our country. For liquid transportation: water supply, drainage, sewage treatment engineering, mud transportation, ocean water transportation. For gas transportation: gas, steam, liquefied petroleum gas. For structural purposes: as piling pipes and bridges; pipes for wharves, roads, building structures, marine piling pipes, etc.

Product Standards

Spiral seam submerged arc welded steel pipe SY5036-83 for pressurized fluid transportation is mainly used for oil and natural gas pipelines; spiral seam high frequency welded steel pipe SY5038-83 for pressurized fluid transportation is welded by high frequency lap welding. Spiral seam high-frequency welded steel pipes for pressurized fluid transportation. The steel pipe has strong pressure bearing capacity, good plasticity, and is convenient for welding and processing; the spiral seam submerged arc welded steel pipe SY5037-83 for general low-pressure fluid transportation is made by double-sided automatic submerged arc welding or single-sided welding for water, gas, Submerged arc welded steel pipes for conveying general low-pressure fluids such as air and steam.

Commonly used standards for spiral steel pipes are generally divided into: SY/T5037-2000 (ministry standard, also known as spiral seam submerged arc welded steel pipes for ordinary fluid transportation pipelines), GB/T9711.1-1997 (national standard, also known as oil and gas industry transportation steel pipes) The first part of delivery technical conditions: A-grade steel pipe (GB/T9711.2 B-grade steel pipe with strict requirements), API-5L (American Petroleum Institute, also called pipeline steel pipe; which is divided into two levels: PSL1 and PSL2), SY/T5040-92 (spiral submerged arc welded steel pipe for piles).

Post time: Jul-20-2023