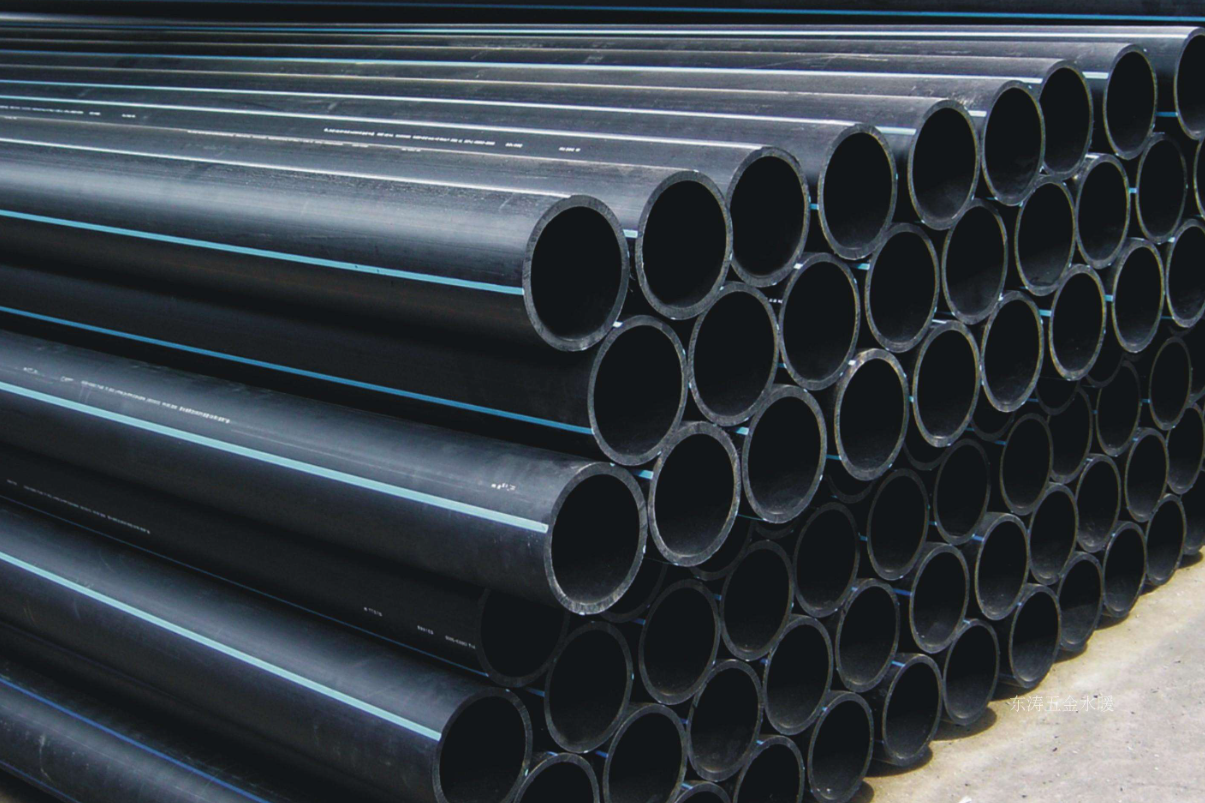

Classification of PE pipes from suppliers

Among all engineering plastics, HDPE ranks first among plastics in terms of wear resistance and is eye-catching. The higher the molecular weight, the more wear-resistant the material is, even surpassing many metal materials (such as carbon steel, stainless steel, bronze, etc.). The service life under strong corrosion and high wear conditions is 4-6 times that of steel pipes and 9 times that of ordinary polyethylene; And improve the conveying efficiency by 20%. The flame retardant and anti-static properties are good and meet the standard requirements. The underground service life exceeds 20 years, with significant economic benefits, impact resistance, wear resistance, and significant dual resistance effects.

PE pipes for sewage discharge, also known as high-density polyethylene pipes, also known as HDPE. This type of pipe is often used as municipal engineering pipe, mainly in the sewage treatment industry. Due to its characteristics of wear resistance, acid resistance, corrosion resistance, high temperature resistance, and high pressure resistance, it has gradually replaced traditional pipes such as steel pipes and cement pipes in the market. Especially because this pipe is lightweight and easy to install and move, it is the choice of new materials. When users choose pipes made of this material, they should also pay special attention to the following points: 1. The selection of plastic pipe materials should be particularly careful. There are thousands of grades of polyethylene raw materials, and there are raw materials as low as a few thousand yuan per ton on the market. The products produced from these raw materials cannot be constructed, otherwise it will cause huge rework losses. 2. The selection of pipeline manufacturers should be based on legitimate and professional manufacturers. 3. When choosing to purchase PE pipes, it is necessary to conduct on-site inspections of the manufacturer to see if they have the production capacity.

PE pipes for water supply are a replacement product of traditional steel pipes and polyvinyl chloride drinking water pipes. The water supply pipe must withstand a certain amount of pressure, usually using PE resin with high molecular weight and good mechanical properties, such as HDPE resin. LDPE resin has low tensile strength, poor pressure resistance, poor rigidity, poor dimensional stability during molding and processing, and is difficult to connect, making it unsuitable as a material for water supply pressure pipes. But due to its high hygiene indicators, PE, especially HDPE resin, has become a commonly used material for producing drinking water pipes. HDPE resin has low melt viscosity, good flowability, and is easy to process, so the selection range for its melt index is also relatively wide, usually with MI between 0.3-3g/10min.

Shandong Kungang Metal Technology Co., Ltd. supplies PE pipes year-round, and can store various specifications and models in the warehouse. Over the years, our company has adhered to the principle of “reputation, service, and quality are life” in the process of rapid development with a sincere attitude. We have accumulated strong strength, laid a good market foundation, and made many partners at home and abroad. Looking forward to our cooperation!

Post time: May-31-2024