Duplex stainless steel

Duplex stainless steel (DSS) refers to stainless steel with ferrite and austenite accounting for about 50% each, and the content of the minor phase generally needs to reach at least 30%. In the case of low C content, the Cr content is 18%~28%, and the Ni content is 3%~10%. Some steels also contain alloying elements such as Mo, Cu, Nb, Ti, and N.

Duplex stainless steel has the following performance characteristics:

(1) Molybdenum-containing duplex stainless steel has good chloride stress corrosion resistance under low stress. Generally, 18-8 type austenitic stainless steel is prone to stress corrosion cracking in neutral chloride solutions above 60°C. Heat exchangers, evaporators and other equipment made of this type of stainless steel have a tendency to produce stress corrosion cracking in trace chloride and hydrogen sulfide industrial media, while duplex stainless steel has good resistance.

(2) Molybdenum-containing duplex stainless steel has good pitting corrosion resistance. When having the same pitting resistance equivalent value (PRE=Cr%+3.3Mo%+16N%), the critical pitting potential of duplex stainless steel and austenitic stainless steel is similar. The pitting corrosion resistance of duplex stainless steel and austenitic stainless steel is equivalent to that of AISI 316L. The pitting and crevice corrosion resistance of high chromium duplex stainless steel containing 25% Cr, especially nitrogen, exceeds that of AISI 316L.

(3) It has good corrosion fatigue and wear corrosion resistance. Under certain corrosive media conditions, it is suitable for making power equipment such as pumps and valves.

(4) It has good comprehensive mechanical properties. It has high strength and fatigue strength, and its yield strength is twice that of 18-8 austenitic stainless steel. The elongation in the solid solution state reaches 25%, and the toughness value AK (V-notch) is above 100J.

(5) It has good weldability and low thermal cracking tendency. Generally, no preheating is required before welding, and no heat treatment is required after welding. It can be welded with dissimilar materials such as 18-8 austenitic stainless steel or carbon steel.

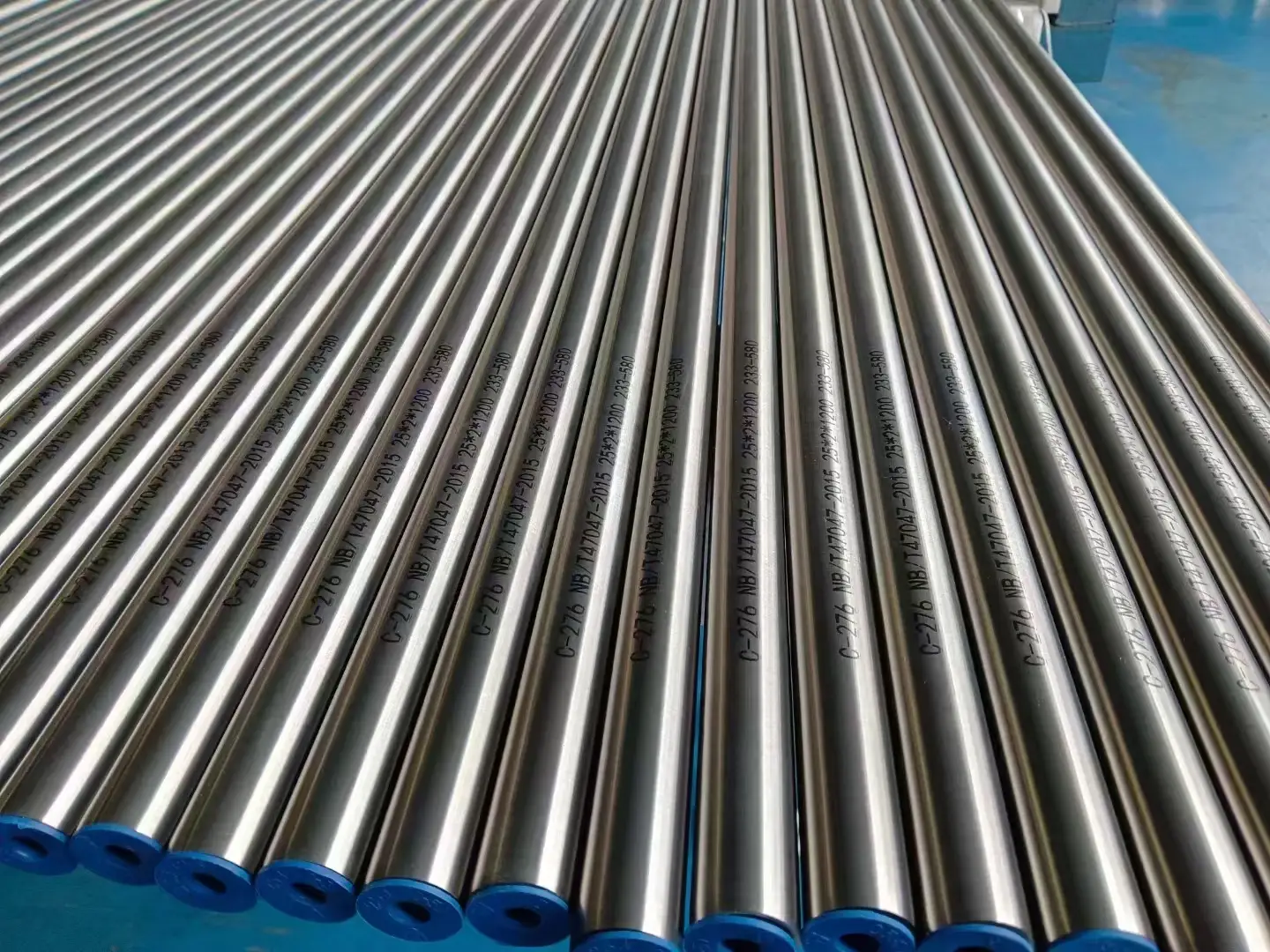

(6) The hot working temperature range of duplex stainless steel containing low chromium (18%Cr) is wider than that of 18-8 austenitic stainless steel, and its resistance is low. It can be directly rolled into billets to produce steel plates without forging. The hot working of duplex stainless steel containing high chromium (25%Cr) is slightly more difficult than that of austenitic stainless steel, and it can produce products such as plates, tubes and wires.

(7) The work hardening effect during cold working is greater than that of 18-8 austenitic stainless steel. In the early stage of deformation of tubes and plates, a large stress needs to be applied to deform.

(8) Compared with austenitic stainless steel, it has a large thermal conductivity and a small linear expansion coefficient, and is suitable for use as equipment lining and production of composite plates. It is also suitable for making the core of heat exchangers, and its heat transfer efficiency is higher than that of austenitic stainless steel.

(9) It still has various brittle tendencies of high chromium ferritic stainless steel and is not suitable for use under working conditions above 300°C. The lower the chromium content in duplex stainless steel, the less harmful the brittle phases such as σ are.

Post time: Jan-16-2025