Duplex stainless steel refers to a material whose microstructure is composed of ferrite and austenite, each accounting for about 50%. In actual use, it is more appropriate for one of the phases to be between 40-60%.

According to the characteristics of the two-phase structure, by properly controlling the chemical composition and heat treatment process, the excellent toughness and weldability of austenitic stainless steel are combined with the higher strength and chloride stress corrosion resistance of ferritic stainless steel, making duplex stainless steel a type of steel that combines excellent corrosion resistance, high strength and easy processing and manufacturing. Their physical properties are between austenitic stainless steel and ferritic stainless steel, but closer to ferritic stainless steel and carbon steel. The resistance to chloride pitting and crevice corrosion of duplex stainless steel is related to the content of chromium, molybdenum and nitrogen. Its resistance to pitting and crevice corrosion can be similar to that of 316 stainless steel, or higher than that of stainless steel for seawater, such as 6%MO austenitic stainless steel. All duplex stainless steels are significantly more resistant to chloride stress corrosion cracking than 300 series austenitic stainless steels, and their strength is also much higher than austenitic stainless steels, while showing good plasticity and toughness.

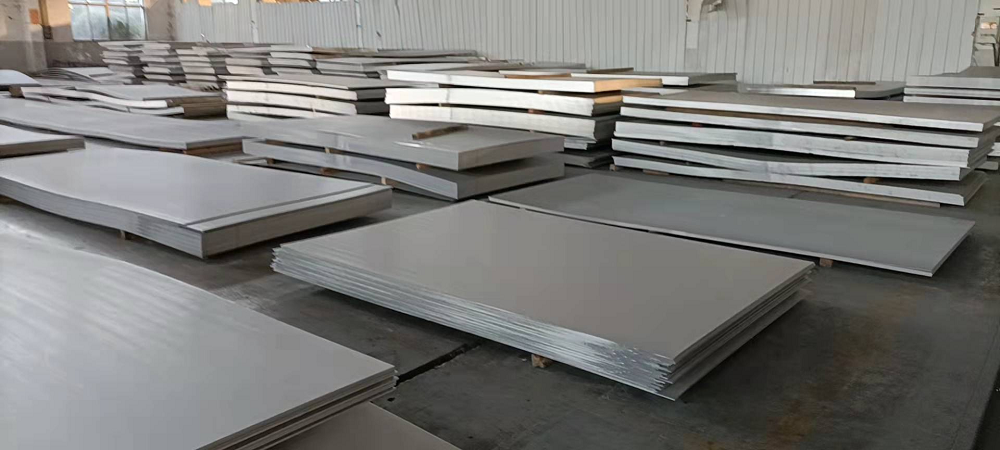

Various product forms of duplex stainless steel: Plates and strips Pipes—welded pipes and seamless pipes Forgings Pipe fittings and flanges Rods and wires

Duplex stainless steel can generally be divided into four categories:

One: Low alloy type, representative grade UNSS32304, steel does not contain molybdenum, PREN: 24-25, can replace AISI 304 or 316 in terms of stress corrosion resistance.

Two: Medium alloy type, representative grade UNSS31803, PREN: 32-33, corrosion resistance is between AISI316L and 6%MO+N austenitic stainless steel.

Three: High alloy type, generally containing 25% Cr, also contains molybdenum and nitrogen, some also contain copper and tungsten, standard grades are UNSS32550, PREN: 38-39, corrosion resistance is higher than 22% Cr duplex stainless steel.

Four: Super duplex stainless steel type, containing high molybdenum and nitrogen, standard grades are UNSS32750, some also contain tungsten and copper, PREN>40, can be used in harsh medium conditions, with good corrosion resistance and mechanical comprehensive properties, comparable to super austenitic stainless steel. (Note: PREN: pitting resistance equivalent value)

Chemical composition The main alloying elements of duplex steel are Cr, Ni, Mo and N. Among them, Cr and Mo are used to increase the ferrite content, while Ni and N are austenite stabilizing elements. Some steel grades also have elements such as Mn, Cu, and W. Cr, Ni, and Mo can improve corrosion resistance. Its resistance to pitting and crevice corrosion is particularly good in chloride-containing environments.

Advantages of duplex stainless steel

1. Compared with austenitic stainless steel

1) The yield strength is more than double that of ordinary austenitic stainless steel, and it has sufficient plasticity and toughness required for forming. The thickness of storage tanks or pressure vessels made of duplex stainless steel is 30-50% less than that of commonly used austenitic stainless steel, which is conducive to reducing costs.

2) It has excellent resistance to stress corrosion cracking, especially in environments containing chloride ions. Even duplex stainless steel with the lowest alloy content has higher resistance to stress corrosion cracking than austenitic stainless steel. Stress corrosion is a prominent problem that ordinary austenitic stainless steel is difficult to solve. 3) The corrosion resistance of the most common 2205 duplex stainless steel used in many media is better than that of ordinary 316L austenitic stainless steel, and super duplex stainless steel has extremely high corrosion resistance. In some media, such as acetic acid and formic acid, it can even replace high-alloy austenitic stainless steel and even corrosion-resistant alloys. 4) It has good local corrosion resistance. Compared with austenitic stainless steel with the same alloy content, its wear corrosion resistance and corrosion fatigue resistance are better than austenitic stainless steel. 5) The linear expansion coefficient is lower than that of austenitic stainless steel, close to that of carbon steel, suitable for connection with carbon steel, and has important engineering significance, such as the production of composite plates or linings.

2. Compared with ferritic stainless steel, the advantages of duplex stainless steel are as follows:

1) The comprehensive mechanical properties are higher than those of ferritic stainless steel, especially plastic toughness. It is not as sensitive to brittleness as ferritic stainless steel.

2) Except for stress corrosion resistance, other local corrosion resistance is better than ferritic stainless steel.

3) Cold processing performance and cold forming performance are much better than ferritic stainless steel.

4) The welding performance is much better than ferritic stainless steel. Generally, no preheating is required before welding and no heat treatment is required after welding.

5) The application range is wider than that of ferritic stainless steel.

Application

Due to the high strength of duplex steel, it can often save materials, such as reducing the wall thickness of the pipe. Take SAF2205 and SAF2507W as examples. SAF2205 is suitable for use in chlorine-containing environments. This material is suitable for oil refining or other process media mixed with chlorides. SAF2205 is particularly suitable for heat exchangers that use chlorine-containing aqueous solutions or slightly salty water as cooling media. This material is also suitable for diluted sulfuric acid solutions and pure organic acids and their mixtures. For example: oil pipes in the oil and gas industry: crude oil desalination in refineries, sulfur-containing gas purification, wastewater treatment equipment; cooling systems using slightly salty water or chlorine-containing solutions.

Post time: Feb-05-2025