Hot-dip galvanized steel sheet: The coating of hot-dip galvanized steel sheet is thick (about 60-600 grams per square meter), and the performance of the substrate is affected by the hot-dip galvanizing process. use

Electro-galvanized steel sheet: The coating of electro-galvanized steel sheet is relatively thin (about 10-160 grams per square meter), and the performance of the substrate is not affected by the electro-galvanizing process.

Gas, color-coated substrates, etc., generally need to be painted, and should not be used directly in the open air.

Zinc layer adhesion amount: In general, Z+ number is used to indicate the weight of zinc layer on both sides of galvanized sheet per square meter, for example: Z10 Z120 (Z12) Z180 (Z18) indicates that the amount of double-sided zinc per square meter is 100 grams 120 180 grams

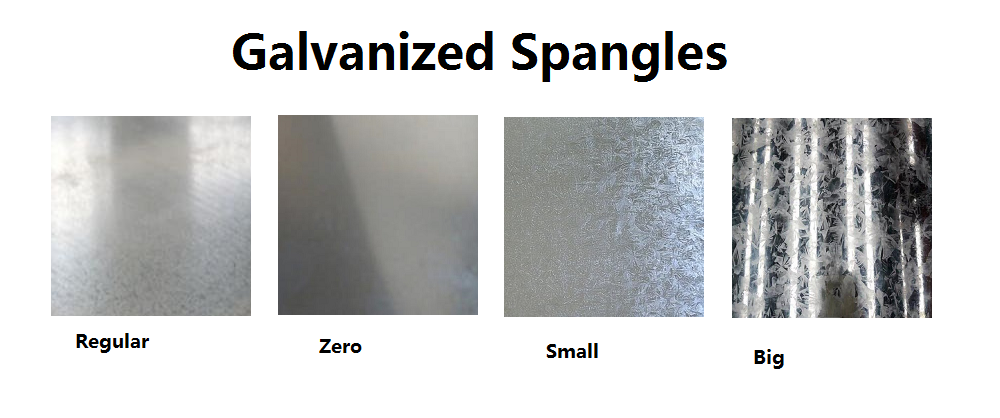

Large spangle (general spangle): After the steel plate is hot-dip plated under the condition that the zinc solution contains antimony or lead, during the normal solidification process, the zinc grains grow freely and form the spangle.

Small spangle (fine spangle): Because the crystal growth of the spangle is controlled, the surface grain structure is small; because the surface is uniform, the surface quality after painting is excellent; the paintability is better than

Regular spangles.

No spangle (wen spangle): because the growth of zinc particles is completely controlled in the process of molten zinc fixing, it is difficult to see the spangle with the naked eye; because the surface is uniform, the surface quality after painting is

excellent

Smoothing spangle: After the molten zinc is solidified, it is smoothed to obtain a very smooth surface; due to the smoothing of the surface, the surface quality after painting is excellent

Post time: Jun-24-2022