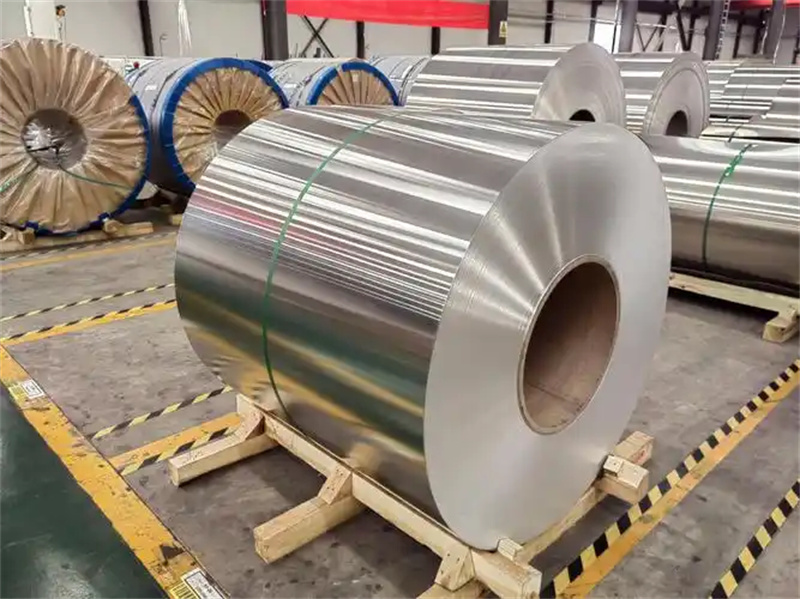

Hot-rolled aluminum coil

[State] O, H32, H34, H36, H38, H111, H112

[Classification] Hot-rolled coil, hot-rolled aluminum coil, etc.

[Thickness] 0.02mm – 12.00mm

[Width] 20mm – 2600mm

[Length] 20mm – 8000mm

[Surface treatment] Single-sided or double-sided lamination, paper addition, and other additional aluminum plate processes

[Technical parameters] National standard mm thickness, support customization, thickness positive and negative tolerance 0.02mm

[Packaging] Simple packaging, three-layer moisture-proof fine packaging, logistics packaging, foreign trade shipping packaging [fumigation wooden pallet]

[Transportation] Self-pickup, logistics, tax-inclusive delivery

[Hot-rolled aluminum coil density] 2.7

[Hot-rolled aluminum coil uses] Sheet metal, instrument panel, street lamp support frame and bolts, processing and customized hardware products, household appliance housing, etc.

Introduction to hot-rolled aluminum coil

Hot-rolled aluminum coil is made by heating aluminum plate ingots, smelting and casting into flat ingots at high temperatures, and cold-rolling by hot rolling mills after milling and uniform quenching. Secondly, the supply of raw materials is different: the difference between the two is the supply of billets. Hot-rolled billets are forged scrap aluminum-heated-cold rolled into coils for cold rolling, while cold-rolled billets are rolled coils-cold rolled cold rolled. Secondly, due to the difference in production process, the cold-rolled aluminum sheet and hot-rolled aluminum sheet have different properties: hot-rolled aluminum sheet has good process performance, strong physical properties and plasticity, and the oxidation effect is the best.

Advantages of hot-rolled aluminum coils

1. Hot rolling can significantly reduce energy consumption and control costs. During hot rolling, the plastic deformation of metal materials is high and the deformation resistance is low, which greatly reduces the calorie consumption of metal deformation.

2. Hot rolling can improve the processing and use properties of metal materials and aluminum alloys, crush the coarse crystals in the forging state, significantly heal cracks, reduce or eliminate welding defects, change the cast structure into a deformed structure, and improve the processing properties of aluminum alloys.

3. Hot rolling generally uses large casting and large reduction cold rolling, which not only improves productivity, but also creates conditions for increasing the cold rolling rate and achieving the continuity and automation of the cold rolling process.

Uses of hot-rolled aluminum coils

Most hot-rolled aluminum coil manufacturers still use the old “horizontal continuous casting → sawing → single extruder hot rolling → cold rolling” or “rolling → cold rolling” equipment and processes for production. The application of hot rolling units is still very limited, especially the installation and application of the “1 4″ type aluminum hot rolling production line is still very limited.

Processing steps of hot-rolled aluminum coils

Hot-rolled aluminum coils refer to aluminum and aluminum alloy plates with a thickness of not less than 7.0. The main types are hot-rolled plates, quenched plates, heat-treated or heat-treated pre-stretched plates, etc. Hot-rolled thick plates are generally produced by the block sheet method in the hot rolling mill. The traditional production process is: casting uniformity-milling-heating-hot rolling-fixed length cutting-straightening.

Hot-rolled aluminum coil process

The hot rolling process of hot-rolled aluminum coils includes the preparation process of cold-rolled raw materials and the cold rolling process. The preparation process of cold-rolled raw materials includes cutting of the casting head and tail, side milling or planing, milling, etching, welding or bundling of aluminum plates or sandwich panels, and heating. The cold rolling process includes rough rolling and fine rolling. The cold rolling process is mainly the process of interaction between hot-rolled strip, ingot and moisturizing emulsion.

Hot-rolled aluminum coil generally refers to cold rolling above the hardening temperature of metal. During the hot rolling process, the metal deforms and there are hardening and softening processes. Due to the influence of deformation rate, as long as the reaction and hardening processes cannot be carried out in time, the metal will cause the most cold hardening with the increase of deformation level. However, within the hot rolling temperature range, the softening process plays a dominant role. Therefore, at the end of hot rolling, the hardening of the metal is often not complete. The hot-rolled aluminum amorphous strip shows a coexistence of hardening and deformation mechanisms.

Post time: Apr-23-2025