How to prevent false welding during the welding of 304 stainless steel square tubes?

304 stainless steel pipes can only be used after processing. Welding is an important step in the processing. Generally, welding methods include manual welding, metal electrode gas shielded welding, tungsten inert gas shielded welding, and combination welding technology.

Virtual soldering is caused by technical issues. Here are some suggestions to prevent virtual soldering:

1. Ensure the quality and suitability of the docking fixture. The docking fixture should be strong enough to ensure that the connecting parts remain stable during the welding process. If the docking fixture is not firm enough, the connector may move or deform, leading to the occurrence of virtual welding.

2. Mill the connecting parts before welding. Use a milling cutter to treat the contact surface of the connector to ensure sufficient contact and fusion during welding. When welding, attention should be paid to ensuring that the excess length at one end does not exceed 200mm to avoid uneven welding and virtual welding.

3. Control heating and collision speed. If the heating and collision speed is too fast, the melted part of the connector may be squeezed onto both sides of the inner and outer walls, causing insufficient fusion and resulting in virtual welding. During the processing, the speed of the machine should be controlled to ensure full fusion of the fusion.

In summary, to prevent false welding during the welding of 304 stainless steel square tubes, attention should be paid to the quality and suitability of the docking fixture, milling treatment should be carried out, and heating and collision speed should be controlled. Only when the technical operation is mature can the occurrence of virtual welding be effectively reduced.

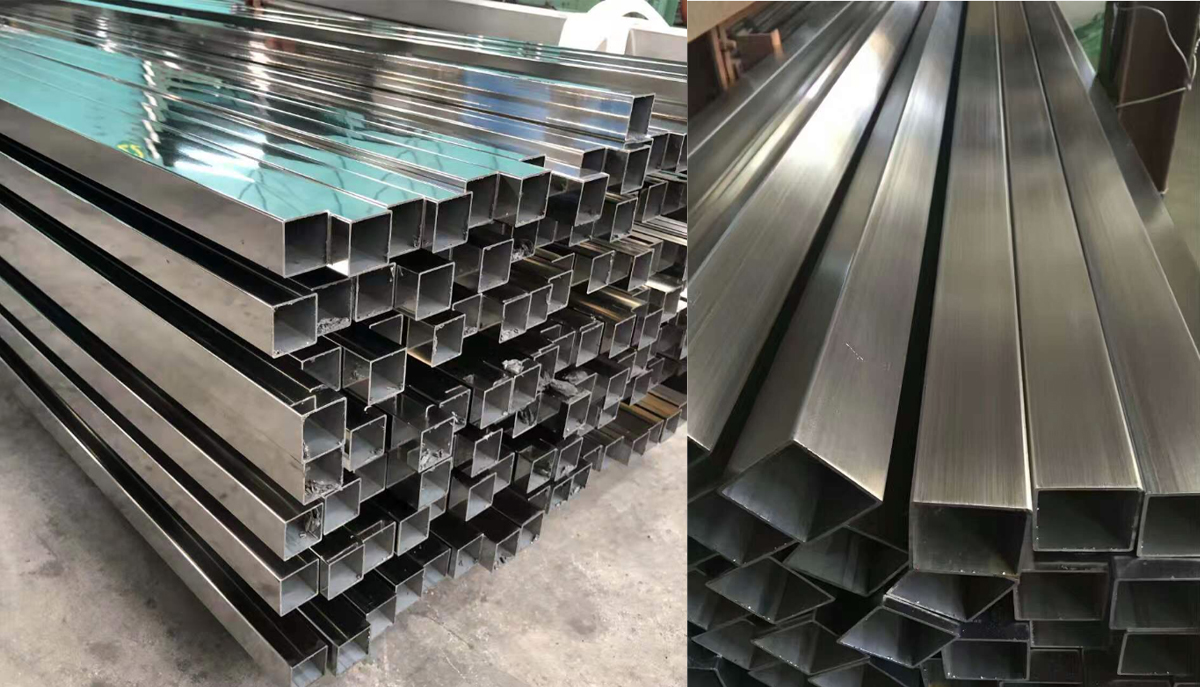

Shandong Kungang Metal Technology Co., Ltd. specializes in various specifications and materials of steel pipes, which can be designed and produced according to customer drawings. With strong production capacity and technical team, welcome to visit the factory for inspection!! The company will adhere to the corporate philosophy of “integrity, development, and win-win”. For many years, the company has relied on well-known factories as solid backing to ensure high-quality and cost-effective products. Currently, it has reached an advanced level in the same industry and is highly trusted and praised by users.

Post time: Jul-03-2024