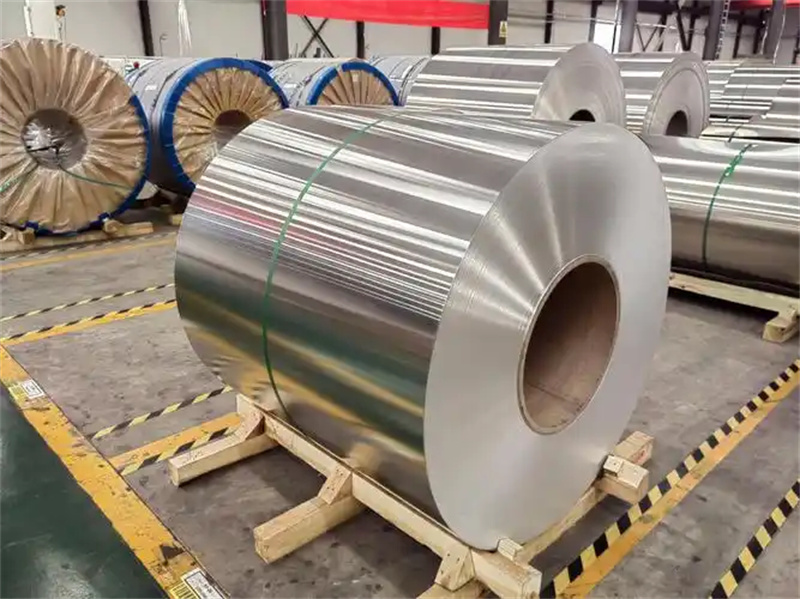

[Brand] Insulation aluminum coil

[State] O, H22, H24, H18, H14, H26, H16

[Classification] Insulation aluminum coil, pipeline insulation aluminum coil

[Thickness] 0.02mm - 12.00mm

[Width] 20mm - 2600mm

[Length] 20mm - 8000mm

[Surface treatment] Single-sided or double-sided lamination, paper addition, and other additional aluminum plate processes

[Technical parameters] Corrosion resistance, stable alloy performance, good quality, low density

[Packaging] Simple packaging, three-layer moisture-proof fine packaging, logistics packaging, foreign trade shipping packaging (fumigation wooden pallet)

[Use of insulation aluminum coil] Pipeline insulation, shell wrapping, stamping processing and other fields

Overview of insulation aluminum coil

Insulation aluminum coil is the most commonly used aluminum coil strip in our current life, especially in pipeline insulation. From the previous 1060 insulation aluminum coil to the more commonly used 3003 thin aluminum coil, it has gradually become an alternative product in the insulation industry. Why do we frequently use 3003 or 1000 alloy as the main insulation material? By wrapping the pipe material, it can achieve the aesthetics of the outer decoration and the function of warm wrapping the pipe. However, with the emergence of thermal insulation aluminum coil, a great opportunity has been opened up for the insulation market, especially the 1060 thermal insulation aluminum coil that we use more now. Its density is relatively small, and compared with steel and iron, its performance is better and its life is longer. The life of conventional thermal insulation aluminum coil is generally about 10 years. Introduction to pipeline thermal insulation aluminum coil In fact, the main use of thermal insulation aluminum coil is the use of pipeline thermal insulation aluminum. We have experienced more and seen more, that is, on the pipeline. Therefore, the name of thermal insulation aluminum coil comes from pipeline insulation materials, which are summarized by people who use more, thus forming a large market. This market is the insulation market, which is what we often call insulation materials or thermal insulation aluminum coils. There is no lack of market recognition and some more professional and well-known companies, which are increasingly choosing aluminum coils as pipe insulation materials. In addition to the conventional factors of good quality, low density and light material, the core is that aluminum coils corrode and are not easy to fall off like iron.

Classification of insulation aluminum coil alloys

1060 insulation aluminum coil

The most common of the 1 series alloys should be 1060 insulation aluminum coil, of course, not just because of its high price. It has a great influence in the insulation market, because many friends or workers have been using iron sheets or galvanized iron sheets as the main use before contacting insulation aluminum coils, that is, pipeline use, but since pure aluminum coils. That is, what we call 1060 aluminum coils, the market has gradually begun to use 1060 aluminum coils as pipeline insulation aluminum coils.

So it is not difficult for us to see how popular 1060 aluminum coils are in the market, but we can't just think about it? Why is 1060 aluminum coil so popular in the market? In fact, there are many reasons. For example, 1060 aluminum coil has the highest aluminum content among aluminum coils. It is also a product with a relatively low density in the entire aluminum strip series. Therefore, it is widely used and reported by users, so it occupies a large market share.

3003 Insulation Aluminum Coil

Friends who are familiar with 3003 alloy know that 3003 is also commonly known as rust-proof aluminum coil. We all know that 303 alloy contains 1%~1.5% manganese metal elements, so its aluminum content is generally above 98%E or the manganese content reaches more than 1%. Therefore, 3003 alloy aluminum coil is a product that is gradually becoming more and more popular in the insulation market, because the addition of manganese elements makes the life of 3003 Baowen Traveler longer than that of conventional 1060 insulation aluminum coil, especially in coastal areas, such as Guangdong, Zhejiang, Jinan, Guiyang, Guizhou and other places, especially in areas where 3003 aluminum coils are used as insulation projects.

Post time: Apr-08-2025