Ppgi Coil Color Coated Steel Coil - PPGI prepainted RAL galvanized gi color coated steel coil – Ruigang

Ppgi Coil Color Coated Steel Coil - PPGI prepainted RAL galvanized gi color coated steel coil – Ruigang Detail:

Product Details

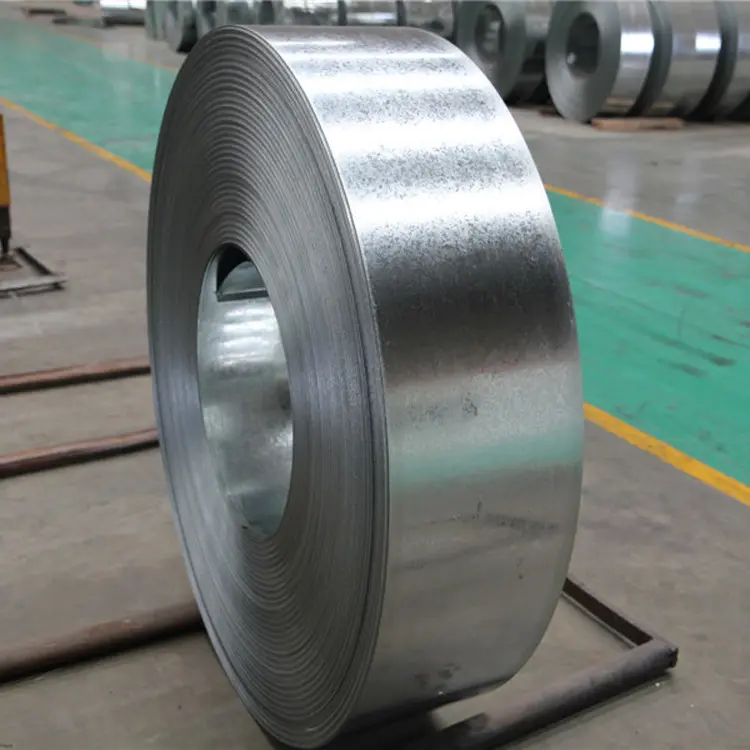

Color-coated coils are based on hot-dip galvanized sheet, hot-dip galvanized sheet, etc., and undergo surface pretreatment (chemical degreasing and chemical conversion treatment).

After that, one or several layers of organic coatings are applied on the surface, and then the product is cured by baking. Also painted with various

The color organic paint color steel coil is named after this, referred to as color coated coil.

In addition to the zinc layer protection, the color coated steel strip using hot-dip galvanized steel strip as the base material is covered and protected by the organic coating on the zinc layer

It can prevent the steel strip from rusting, and its service life is about 1.5 times longer than that of the galvanized strip.

use

Color-coated coils are based on hot-dip galvanized sheet, hot-dip galvanized sheet, etc., and undergo surface pretreatment (chemical degreasing and chemical conversion treatment).

After that, one or several layers of organic coatings are applied on the surface, and then the product is cured by baking. Also painted with various

The color organic paint color steel coil is named after this, referred to as color coated coil.

The color-coated steel strip using hot-dip galvanized steel strip as the base material is protected by the zinc layer, and the organic coating on the zinc layer plays a covering and protective role to prevent the steel strip from rusting, and the service life is longer than that of the galvanized strip, about 1.5 times.

Type of coating structure

2/1: Apply twice on the upper surface, once on the lower surface, and bake twice.

2/1M: Coat the upper and lower surfaces twice and bake once.

2/2: Coat the upper and lower surfaces twice, and bake twice.

Uses of different coating structures:

2/1: The corrosion resistance and scratch resistance of the single-layer back paint are poor, but it has good adhesion.

To be applied to sandwich panels;

2/1M: The back paint has good corrosion resistance, scratch resistance and processability, and has good adhesion. It is suitable for single-laminated panels and sandwich panels.

2/2: The corrosion resistance, scratch resistance and processability of the double-layer back paint are better, and most of them are used for single-layer paint.

Laminated board, but its poor adhesion, not suitable for sandwich panels.

Product detail pictures:

Related Product Guide:

Gaining purchaser gratification is our company's aim eternally. We're going to make great initiatives to create new and top-quality products, satisfy your exclusive prerequisites and supply you with pre-sale, on-sale and after-sale solutions for Ppgi Coil Color Coated Steel Coil - PPGI prepainted RAL galvanized gi color coated steel coil – Ruigang, The product will supply to all over the world, such as: kazan, Oslo, Mauritania, we are fully determined to control the whole supply chain so as to provide quality products at competitive price in a timely manner. We are keeping up with the advanced techniques, growing through creating more values for our clients and society.

Cooperate with you every time is very successful, very happy. Hope that we can have more cooperation!