Spcc Coil Cold Rolled Steel - High hardness deep drawing Cold-rolled steel sheet – Ruigang

Spcc Coil Cold Rolled Steel - High hardness deep drawing Cold-rolled steel sheet – Ruigang Detail:

Product Details

1. Durable, convenient, quality assurance

2. There are various types of specifications, which can be customized according to specifications

3. Uniform thickness, reliable quality, easy to use and wide range of uses

4. Sufficient inventory and spot supply

Hardness detail:

The surface Rockwell hardness of annealed plain carbon steel is generally 55+-3, and the hardness of unannealed hard-rolled cold-rolled strip steel is above 80. Cold-rolled strip and sheet generally have a thickness of 0.1-3mm and a width of 100-2000mm; both are made of hot-rolled strip or steel plate. .

CRS is the abbreviation of English cool rolled steel, that is, cold rolled steel. It refers to a rolling process of steel. For example, q235 ordinary carbon steel plate can be cold rolled, and 10# steel plate can also be cold rolled. Its hardness can be on the corresponding standard according to the steel grade used. .

What is the grade of cold-rolled sheet harder than spcc? .

Cold-rolled sheet is the abbreviation of ordinary carbon structural steel cold-rolled sheet, also known as cold-rolled sheet, commonly known as cold-rolled sheet, and sometimes mistakenly written as cold-rolled sheet. The cold plate is made of ordinary carbon structural steel hot-rolled steel strip, which is further cold-rolled into steel with a thickness of less than 4mm. .

The cold-rolled sheet is divided into: 1/8 hard, 1/4 hard, 1/2 hard and full hard state. There are generally two main units of hardness value: HRB (Rockwell) HV (Vickers) as follows: Quality distinguishing symbol HRB (Rockwell) HV (Vickers) 1/8 hard. .

Pickling plate is a hot-rolled plate that is subjected to a process such as dephosphorization (removal of rust, residues, etc., produced during hot-rolling) and other processes to pickle the surface to obtain a steel plate with better performance than hot-rolled surface. It can be seen from its manufacturing process that its hardness is hot rolled with the same grade. .

There is basically no difference in surface hardness between cold-rolled and galvanized. Because the galvanized surface is only plated with a layer of zinc from a few microns to about 20 microns on the substrate. The substrates are generally cold-rolled and hot-rolled. The hardness mainly depends on the grade of the material, and the grades vary. .

Take DC01, DC03 as an example. DC01 upper limit of yield strength 280 DC03 upper limit of yield strength 240 , dc06+ze, they correspond to the cold-rolled sheet, the number represents the stamping grade, and the larger the number is.

Cold-rolled sheet is made of hot-rolled coil as raw material, rolled at room temperature below the recrystallization temperature, and its hardness is about 150HV. The shearing machine blades are generally made of tool steel, with a hardness of HRC55~58°, which can cut most of them.

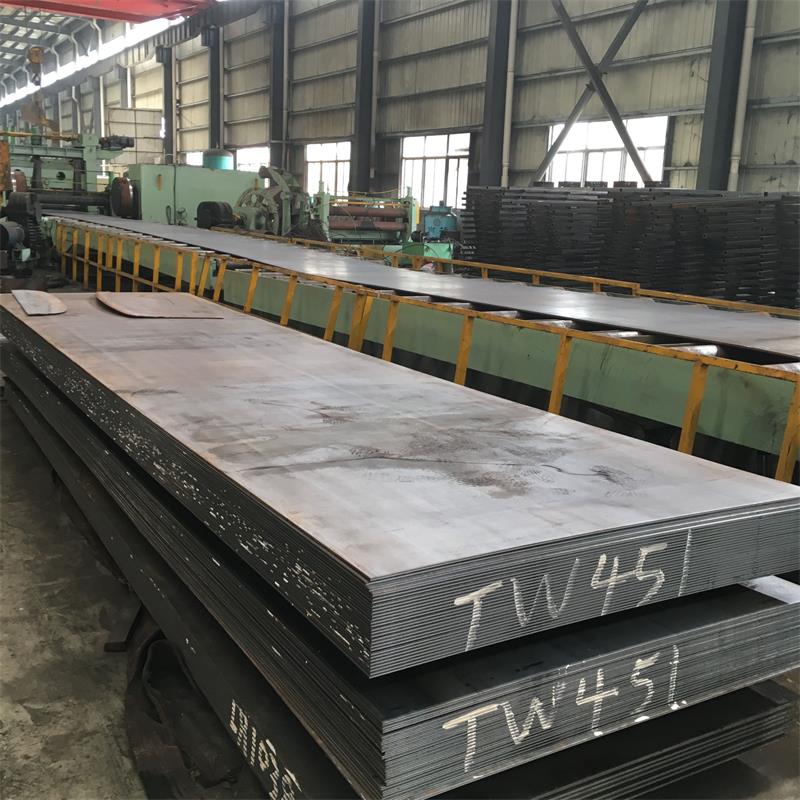

Product detail pictures:

Related Product Guide:

Our business puts emphasis over the administration, the introduction of talented staff, plus the construction of employees building, striving hard to boost the standard and liability consciousness of staff members. Our corporation successfully attained IS9001 Certification and European CE Certification of Spcc Coil Cold Rolled Steel - High hardness deep drawing Cold-rolled steel sheet – Ruigang, The product will supply to all over the world, such as: Islamabad, Sierra Leone, USA, With a team of experienced and knowledgeable personnel, our market covers South America, the USA, the Mid East, and North Africa. Many customers have become our friends after good cooperation with us. If you have the requirement for any of our products, please contact us now. We are looking forward to hearing from you soon.

This supplier stick to the principle of "Quality first, Honesty as base", it is absolutely to be trust.