Steel Coil Manufacturing Furnace - Steel Coil – Ruigang

Steel Coil Manufacturing Furnace - Steel Coil – Ruigang Detail:

Product Specifications

Thickness: 0.2-20mm

Width: 600-3000mm

Formed coils are mainly hot-rolled coils and cold-rolled coils. Hot rolled coil is the processed product before the recrystallization of the steel billet. Cold rolled coil is the subsequent processing of hot rolled coil. The general weight of the steel coil is about 15-30T.

Product Classification

● Hotrolled, that is, hot-rolled coil, which is a slab (mainly for.

● Casting billet) as raw material, after heating, it is made into strip steel by rough rolling unit and finishing rolling unit.

● The hot strip from the last rolling mill of finishing rolling is cooled by laminar flow to the set point.

● The coil is rolled into a steel strip coil by a coiler, and the cooled steel strip coil can be used according to the different needs of users.

● After different finishing lines (leveling, straightening, cross-cutting or slitting, inspection.

● Weighing, packaging and marking, etc.) are processed into steel plates, flat coils and slit steel strip products.

production process

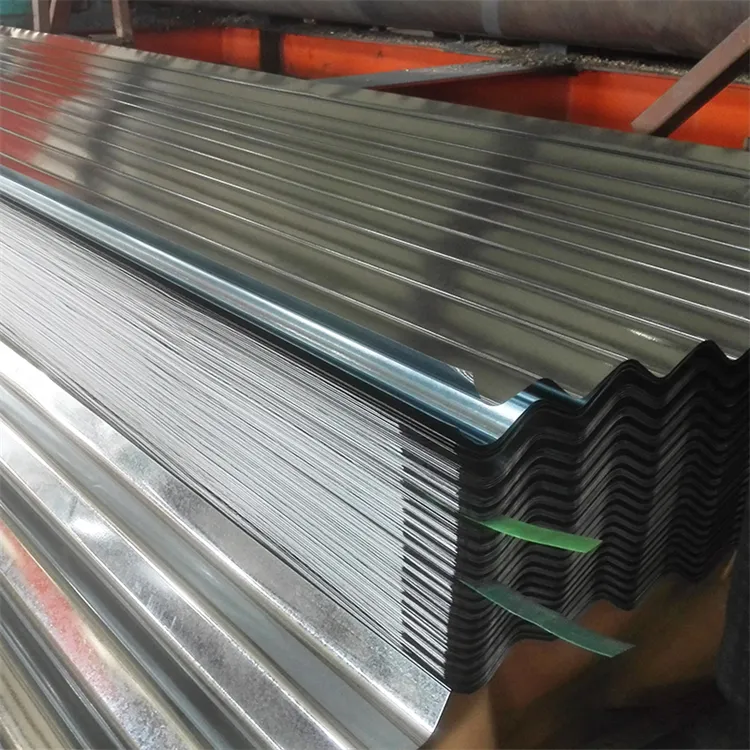

The production process of hot-dip galvanized sheet mainly includes: Original plate preparation → Pre-plating treatment → Hot dip plating → Post-plating treatment → Finished product inspection, etc. According to custom, often according to the pre-plating treatment method of.

The galvanized coil is composed of an aluminum-zinc alloy structure, which is composed of 55% aluminum, 43% zinc and 2% silicon solidified at a high temperature of 600 ° C. The entire structure is composed of aluminum-iron-silicon-zinc, forming a dense A kind of quaternary knot body.

Product Details

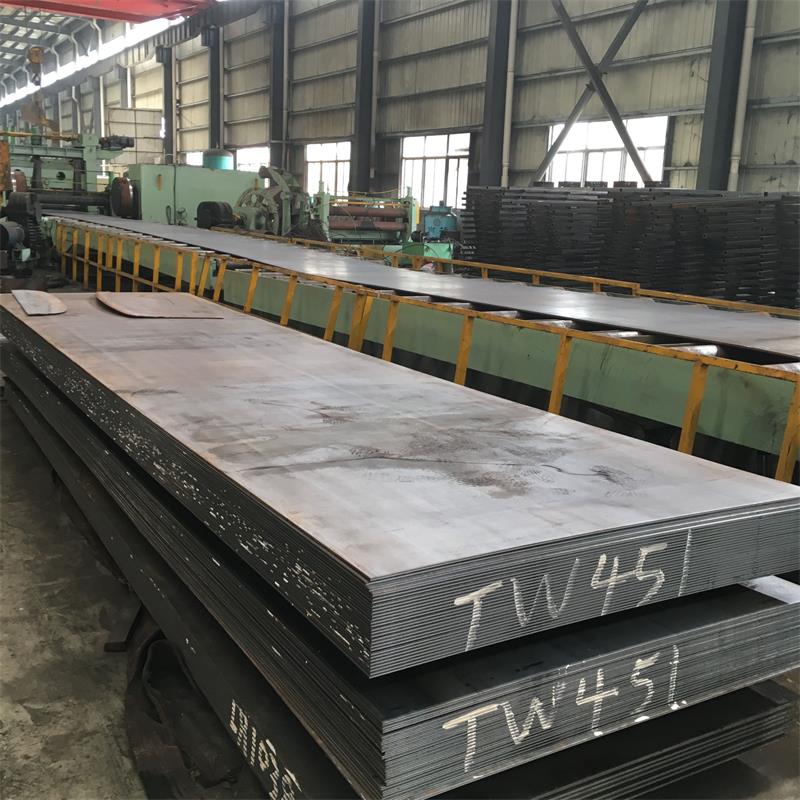

Material: Q235B, Q345B, SPHC510LQ345AQ345E

Cold rolled coil (Coldrolled), commonly used in the steel industry, is different from hot rolled coil.

It refers to directly rolled into a certain thickness with a roll at room temperature and rolled into a whole roll with a winder

steel belt. Compared with hot-rolled coils, cold-rolled coils have a brighter surface and higher finish, but will

More internal stress is generated, and annealing treatment is often carried out after cold rolling.

Category: SPCC, SPCD, SPCE

Galvanized steel coils (Galvanized steel coils), galvanized refers to the metal, alloy or the surface of other materials is plated with a layer of zinc to play the role of beautiful, rust-proof and other surface treatment technology. Now the main method is hot-dip galvanizing.

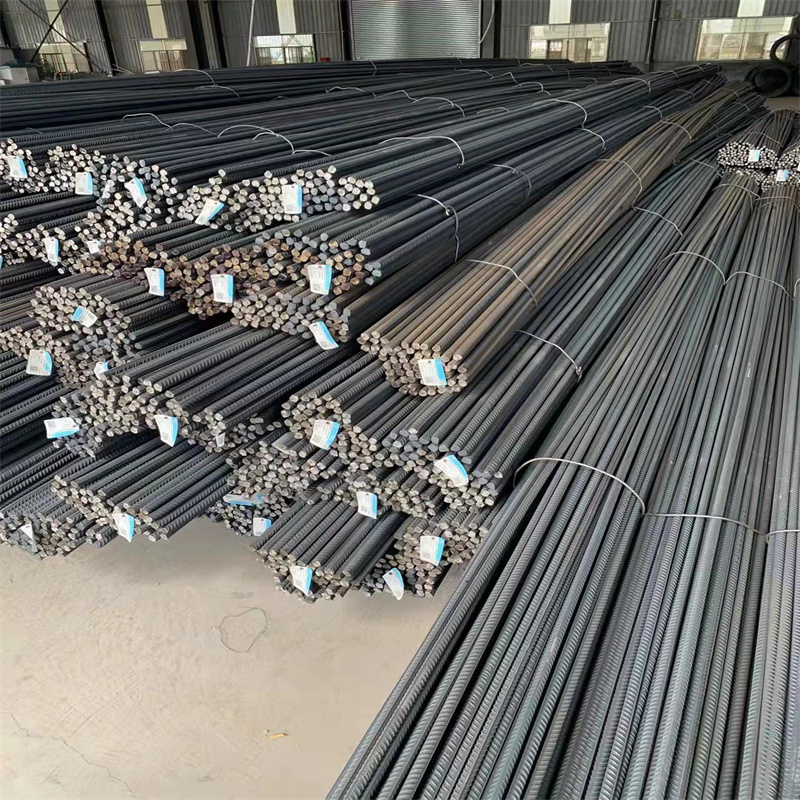

Product detail pictures:

Related Product Guide:

Dedicated to strict top quality command and considerate purchaser support, our experienced staff customers are always available to discuss your necessities and be certain full client gratification for Steel Coil Manufacturing Furnace - Steel Coil – Ruigang, The product will supply to all over the world, such as: Toronto, Slovenia, Rotterdam, Our staffs are rich in experience and trained strictly, with qualified knowledge, with energy and always respect their customers as the No. 1, and promise to do their best to deliver the effective and individual service for customers. The Company pays attention to maintaining and developing the long-term cooperation relationship with the customers. We promise, as your ideal partner, we'll develop a bright future and enjoy the satisfying fruit together with you, with persisting zeal, endless energy and forward spirit.

A good manufacturers, we have cooperated twice, good quality and good service attitude.